CNG Fueling Station – Gemini Compressors

Compressors

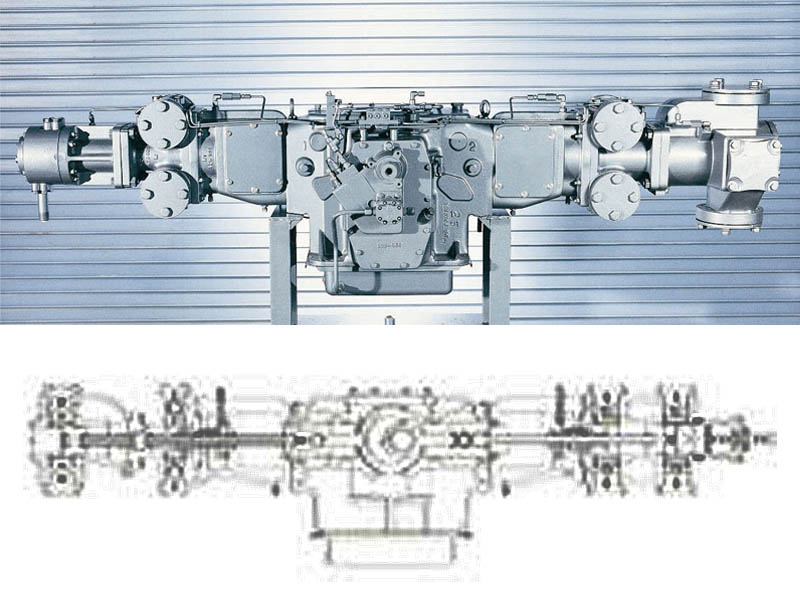

Gemini compressors are known and respected throughout the world for their quality and durability. They are one of the leaders in the market for gas compression, with more than 10,000 compressors installed.

Designed to attend to the most varied applications, the Gemini alternative compressors are available in the widest range of power settings, flows and suction and discharge pressures.

- Horizontal alternative compressors, for up to 4 stages of compression;

- High resistance structure designed for the highest loads and to guarantee a long useful life;

- Balanced compressor cylinders minimize vibration;

- Reliable and of simple maintenance, making for very low service down time;

- Designed for heavy and continuous operations, the compressors are all tested before leaving the factory.

Fueling Stations

The Strauhs CNG fueling stations are compact units, consisting of a compressor unit installed on a metallic structure (skid), containing all the elements necessary for compression, storage and distribution of the gas.

- Direct coupling (without belts)

- Air-gas refrigeration

- Electrical motor drive

- 3 or 4 stage compression

- Explosion-proof and intrinsically safe electrical installation

- Simple and compact design

- Low maintenance

- High performance and reliability

- Electrical panel controlled by PLC

- Suction and discharge filters assure low levels of oil in the gas supply

- Sound insulation enclosure and protection against weather.

Storage Cylinders

Consist of a set of interconnected cylinders mounted on a metallic structure.

- Various sizes and configurations available

- Certified cylinders

- Safety valve

- Pressure Gauge

- Excess flow valves

- Hydrostatically tested to 375 barg

Control Panel

Consists of a steel panel for installation in a non-risk area containing all the elements for the control, monitoring and safety of all the compressor functions.

- Programmable Logic Control (PLC)

- Optional remote communication via modem

- Motor action by “soft-starter”

- Explosion-proof and intrinsically safe electrical installation

- Auto-monitoring of safety of all compressor functions

- Indication on PLC display of compressor operation and alarm messages

Sound and Weather Protection Enclosure

The enclosures provide protection against the weather and attenuate the noise generated by the compressor, maintaining them within the limits suitable for installation in urban areas.

- Sound insulation

- Weather protection

- Built in high resistance steel structure

- External instruments panel

- Doors on all sides for ease of maintenance

- Gas detector at one point with alarm (optional)

- Lifting rings

- Adequate internal space to carry out maintenance

- Internal explosion-proof lighting