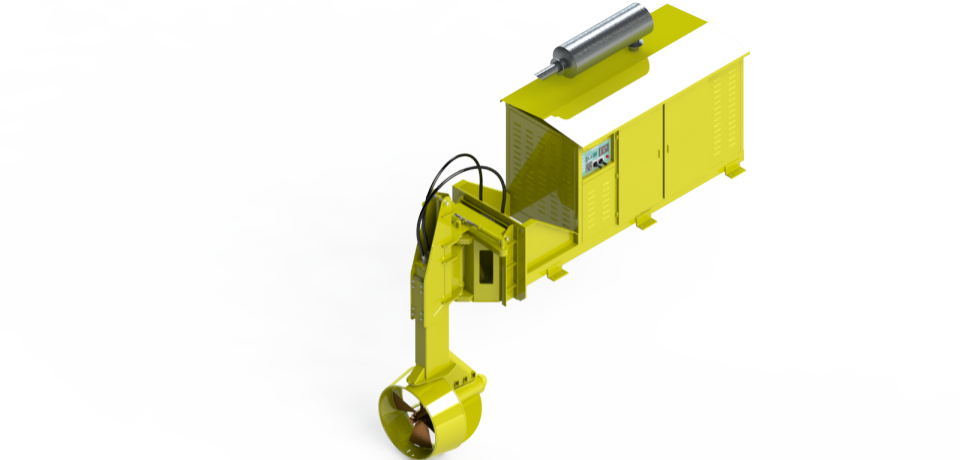

Strauhs outboard thrusters are autonomous propulsion units. The propulsion is integrated into the diesel-hydraulic power unit on a modular skid installed on the deck.

The propeller shaft is directly driven by a hydraulic motor integrated into the lower part of the unit.

Available with power ratings from 100HP to 500HP, the units have 360° rotation with a tilt system that reaches 90° and optional propeller depth adjustment.

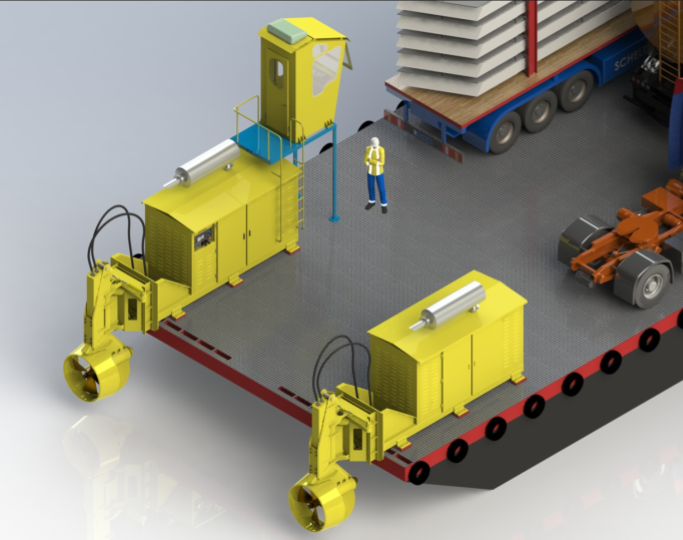

They are ideal propulsions for river ferries, service and maintenance barges, small dredgers, military landing craft, etc.

The conversion of a barge or unpowered vessel can be done in just a few hours and does not require hull modification.

The engine directly drives the variable displacement hydraulic pump. This means that the propeller speed can be precisely controlled at any point between completely static and maximum, both forward and reverse, without changing the engine speed. From full forward to full reverse in a short time, the engine runs at a constant speed, reducing fatigue, increasing engine life, and reducing fuel consumption.

The hydraulic transmission is especially suitable for applications where debris in the water can be a problem. The propeller depth adjustment allows operation in shallow waters.

It requires little maintenance and provides years of operation in the harshest environments. Routine maintenance of the outboard propulsion unit does not require disassembly of the unit, as the tilt mechanism allows the unit to be lifted above the waterline. If desired, the entire unit can be easily removed from the vessel and repaired separately.

The hydraulic transmission provides instant relief from overloads caused by impacts, allowing the unit to tilt, protecting the propulsion and minimizing damage.

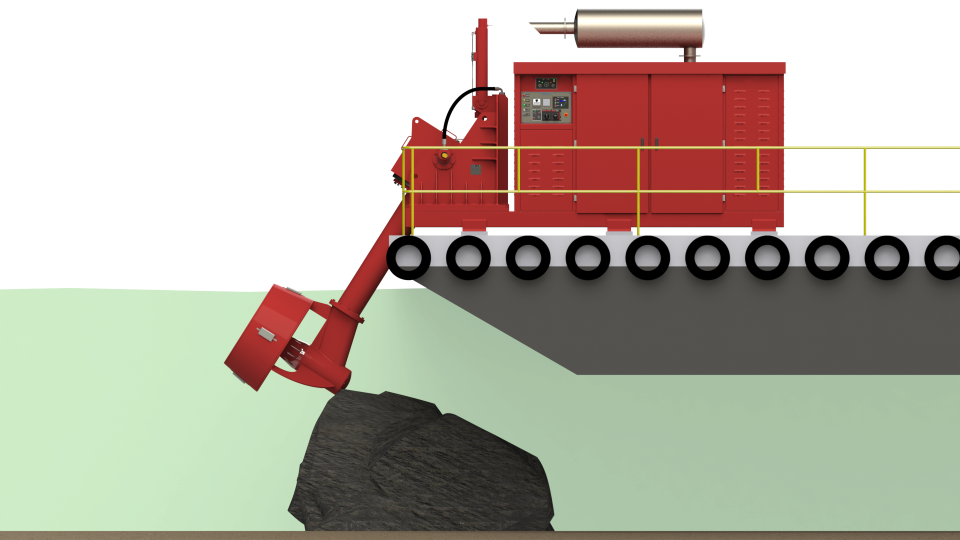

The propulsion unit incorporates a hydraulic power tilt system capable of elevating the outboard drive assembly through an arc of 90 degrees.

The hydraulic power tilt system incorporates cross-port relief valves that allow the outdrive assembly to kick up in the event it encounters a subsurface obstruction, making it ideal for shallow draft applications.

The tilt system allows the elevation of the stem above the water line for inspection or maintenance, permitting repairs without employing divers or dry-docking the vessel.

Here is the link to the demonstration video of our outboard azimuth thruster: https://www.youtube.com/watch?v=xqrHcgh9zyk

An optional propeller depth adjustment mechanism can be provided to vary the propeller depth for light and loaded draft conditions. When the vessel is in shallow water, the propeller can be lifted above or even with the baseline; when in deep water, the propeller can be lowered below the baseline for maximum propulsive efficiency.

Open propulsions are fitted with Gawn-series, 4-blade, high-thrust, manganese-bronze monoblock units. An anti-cavitation plate covers the propeller to prevent vortexing at light ship displacements. Nozzle units are equipped with a Kaplan series, 4-blade, manganese-bronze monoblock propeller inside a Kort 19A style steel nozzle. The propeller diameter, blade pitch, and area ratio are calculated to provide either maximum static bollard thrust or maximum thrust at the required vessel speed, taking into account the vessel draft conditions.

| MODEL |

Model

Diesel Engine Power

Propeller Diameter

Unit Weight

Static Thrust (Bollard Pull)

| HP | kW | MM | POL | KG | KN | |

| STR 140 | 140 | 104 | 670 | 26 | 800 | 10 |

| STR 275 | 275 | 205 | 1000 | 39 | 950 | 20 |

| STR 450 | 450 | 335 | 1100 | 43 | 1500 | 40 |